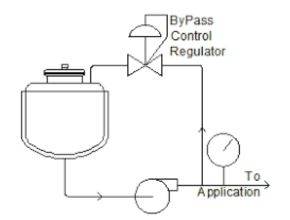

The term bypass valve refers to any valve installed in a bypass line, and is not used to indicate a particular valve shape or configuration. So what types of valves are suitable for installation in bypass piping? The bypass valve allows some fluid to go to the application while the excess fluid bypasses the application and returns to the reservoir. Note that the concept of pressure bypass control works equally well for all types of pumps

The Definition Of Bypass Valve

Bypass valves are designed to divert steam from one part of the system (such as power generation or process steam such as paper and pulp production) to reheat or exhaust piping to safeguard equipment from over-pressure. These differential pressure control valves are designed to cope with pressure and temperature differentials and are used in many applications,

A bypass is a system of pipes, pumps, hoses, and valves that help divert the flow from a pipe section that is under repair or rehabilitation. This temporary diversion allows the flow to continue when the primary line is blocked for rehabilitation.

Bypass pumping is often used in sewer repairs to prevent sewerage from backing up into homes while work is being executed on existing infrastructure. The advantage of bypass pumping is that the water or sewer flow to homes and offices remains uninterrupted during repairs allowing contractors sufficient time to complete the job.

Sewer pipes and water mains require regular repair and maintenance work, and sometimes replacement, in order to keep the system in working condition. Trenchless rehabilitation methods are excellent ways to do so in lesser time and cost and minimal disturbance to the ground surface.

How Bypass Work

The bypass valve carries the flow around the affected line and reconnects to the primary line at a second valve. Opening the bypass valve allows the flow to enter the temporary pipe, and opening the second valve allows the flow to re-enter the primary pipe at a point beyond the problem area. When repairs are completed, both valves are closed to prevent backflow into the temporary line. The flow will be interrupted only long enough to install the bypass, rather than for the whole time required to complete a repair or rehabilitation project. A sewer line bypass generally requires a pump to move sludge into and through the bypass. In this case, the pump acts as the valve at the beginning of the bypass.

- Definition, How to Work, and Applications of Bypass Valve

Applications of Bypass Valves

Bypass valves find applications in various industries and systems where redirecting or regulating the flow of fluids is necessary. Some common applications of bypass valves include:

Oil and Gas Pipelines:

Bypass valves are used in oil and gas pipelines for maintenance and repair activities. They allow the flow to be redirected, bypassing sections that require maintenance or isolation, ensuring uninterrupted operation of the rest of the pipeline.

Water Treatment Plants:

Bypass valves are employed in water treatment plants to divert the flow during maintenance, repair, or replacement of filtration systems, pumps, or other equipment. They ensure continuous water supply while the affected components are serviced.

Cooling Systems:

Bypass valves are used in cooling systems, such as HVAC (Heating, Ventilation, and Air Conditioning) systems, to regulate and control the flow of coolant or chilled water. They can redirect the flow to maintain optimal cooling performance, especially during maintenance or when specific areas require additional cooling.

Refference : https://trenchlesspedia.com/definition/2434/bypass https://www.tlv.com/steam-info/steam-theory/other/bypass-valves