Description

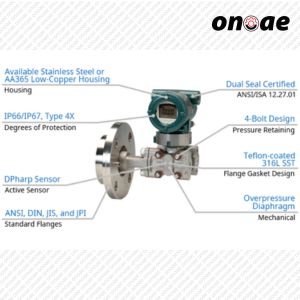

Description of Flange Mounted Differential Pressure Transmitter EJA210E

This model is a flange-mounted differential pressure transmitter from Yokogawa’s EJA210E series, with configuration code JMS4G-917EN-EA14B1SE03-B/HE. This device precisely measures the differential pressure of liquids, gases, or steam, and is suitable for direct integration into process flanges. It provides a digital display and HART/BRAIN communication for field setup and monitoring.

Reviews

There are no reviews yet.