Description

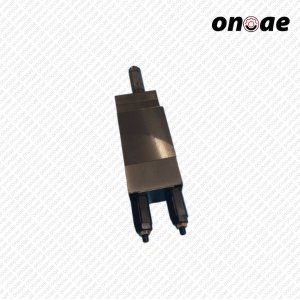

Neodyn 125P Series Pressure Switch/Tamper Proof

Neodyn 125P Series Pressure Switch/Tamper Proof is designed for high-pressure pneumatic or low-impulse hydraulic applications requiring a narrow Deadband and tamper-proof setpoint. Has diaphragm sensor with efficient Nega-Rate ® Belleville disc spring for excellent accuracy and repeatability.

OPTIONS

- Set Points

125P between 20 psig dec. and 3050 psig inc. (1.4 bar dec. and 210 bar inc.) - Wetted Material

1 Aluminum port, Teflon-coated polyimide diaphragm, and Buna-N O-Ring

4 316 Stainless steel port, Teflon coated polyimide diaphragm, and Buna-N O-Ring - Electrical Form

C 11 amp, 1/4 hp at 125 or 250 VAC; 5 amp resistive, 3 amp inductive at 28 VDC; 5 amp resistive at 125 VDC CC 11 amp, 1/4 hp at 125 or 250 VAC; 5 amp resistive, 3 amp inductive at 28 VDC; 5 amp resistive at 125 VDC - Enclosure

3 Meets or exceeds the requirements of NEMA Type 3, 3R, 3S, 4, 4X, and 13, IP65 - Miscellaneous

An Epoxy paint exterior — extra protection for severe environments - B Viton O-Ring

- C EPR O-Ring

- D SIL approval and marking, per IEC61508 (includes FMEA report)

- M Gold electrical contacts for extremely low current applications R 72″ Electrical free leads

- U M20 x 1.5 Electrical Conduit Adapter

- W Stainless steel screws — exterior

- X CSA approved and CE?Mark

- Special (Consult representative or factory)

• Pressure port per SAE AS4355E04

• Non-catalog set point, headband, and/or proof pressure

• Media temperature capability from -65°F to +35

Features

Stable Set Points – “Eliminates Constant Recalibration”

- No moving parts except during actuation—no spring fatigue or wear.

- Set point is mostly a function of the negative rate Belleville spring—variables in snap action electrical have little effect on the set point.

- Total movement of the Belleville spring compensates for any relocation of the electrical due to case growth—consistent set point over temperature change.

- No linkage utilized—no wear which can affect accuracy.

Vibration Resistant – “Eliminates Contact Chatter”

- Belleville spring does not preload the electrical prior to actuation—snap action electrical maintains its vibration resistant characteristic.

- Small mass and inherent stability of the Belleville spring resists chatter caused by vibration.

- Snap action electrical is ruggedly mounted with minimal bracketry—no spring mounted electricals or linkages.

High Over-Pressure Capability – “No Affect on Set Point Accuracy”

- Belleville spring does not contain the pressure—no affect on system or proof pressure capability.

- The pressure sensing portion bottoms out after actuation and is fully supported—pressure sensing parts are designed for high pressure conditions.

- Limited movement of spring mechanism—no overtravel of the snap action electrical due to high pressure.

High Cycle Lifer – “Millions of Cycle”

- Short stroke minimizes wear—Belleville spring mechanism is exercised less than .020″.

- Snap action of Belleville spring reduces electrical arc—prolongs contact life.

Specifications

Model Series

| Adjustable Range Number | Adjustable Set Point Range | Maximum Recommended System Pressure | Proof Pressure |

|---|

| Increasing | Decreasing |

|---|

| 125P | 40 to 3050 | 20 to 2800 | 5000 | 7500 |

*All values given in psig.

Standard Specification

| Model | Weather Proof (NEMA 4 and 13) | Explosion Proof Hermetically Sealed (NEMA 4X, 7, 9 and 13 |

|---|

| Deadband (Differential) | The deadband can be selected anywhere from 20 psig (1.38 bar) or 8% (whichever is greater) to 45% of the set point |

| Electrical | Snap action electrical switch recognized by Underwriters’ Laboratories, Inc. and CSA International | Snap action electrical switch assemblies, Part Numbers 057-0770 & 057-0772 (Form C) and 057-0771 & 057-0773 (Form CC), are listed by Underwriters’ Laboratories, Inc., FM Approvals, CSA International and NCC (INMETRO). See the miscellaneous option N for additional listings. |

| Electrical Connection | 1/2 NPT male conduit connection with PVC insulated 18 AWG leads 18″ long |

| Pressure Connection | 1/4 NPT Female |

| Ambient Temperature Range | – 40°C to + 82°C |

| Media Temperature Range | – 40°C to + 149°C *Temperature limits change with O-Ring selection |

| Shipping Weight | Approximately 10 ounces | Approximately 1 pound |